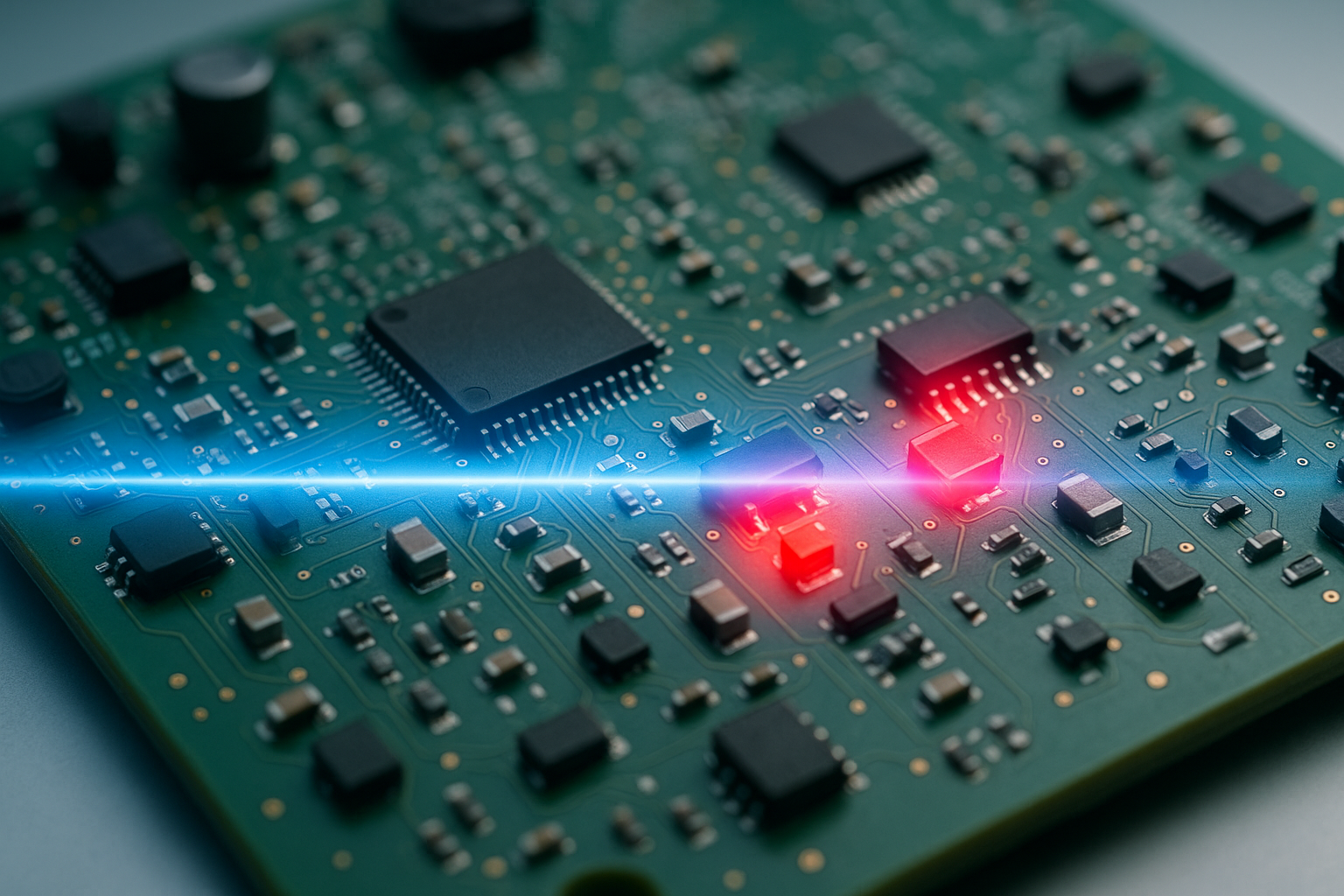

Inspect. Trace. Secure.

Cybord Technology

Our deep learning network evolves with diverse data sources, utilizing Visual-AI, smart algorithms, and big data to drive traceability and authenticity. This guarantees the integrity and reliability of your products, offering 100% accurate information about every component placed on your board.

Cybord's traceability is now a part of the IPC standard and is becoming a test method of the SAE anti-counterfeit testing.

Three Layers of Security

In industries where failure is not an option, Cybord delivers complete assurance - down to the last component. Our Visual-AI platform verifies every part on every board, helping manufacturers maintain the highest standards of integrity and compliance.

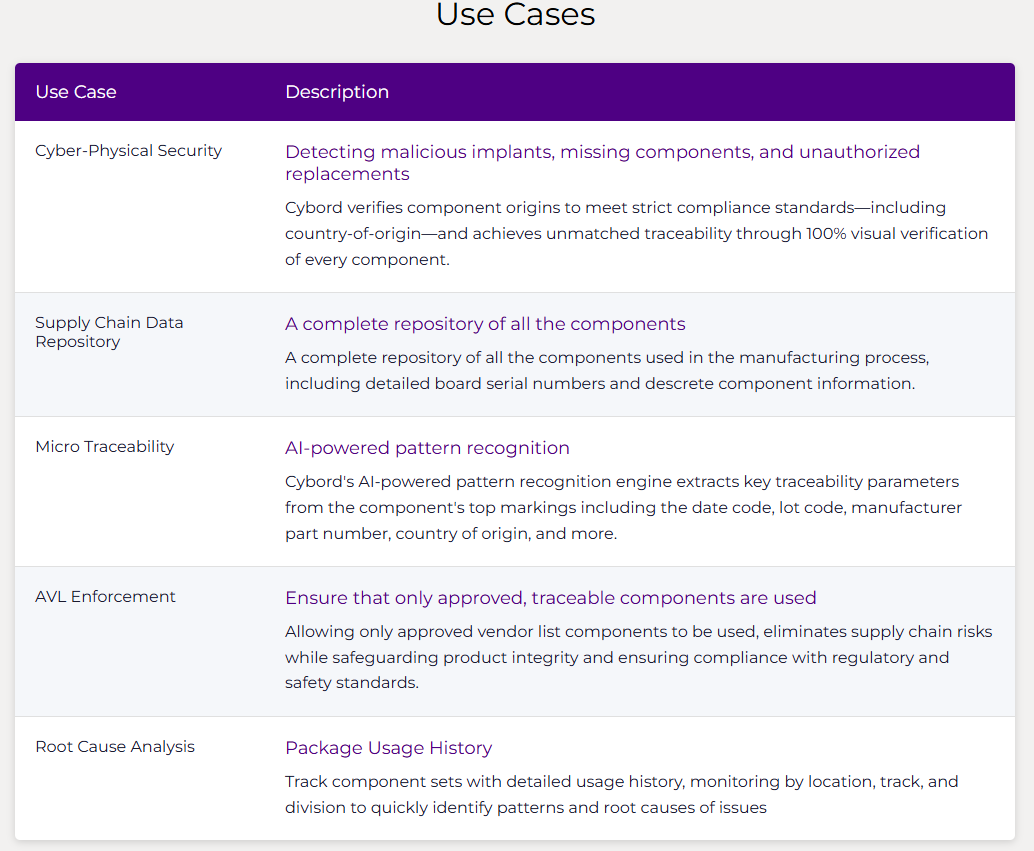

Use Cases

Cybord RTI – Real Time Interceptor

Cybord’s RTI identifies, intercepts and eliminates defective and suspected components before they are assembled on the board.

Read The White Paper

Trusted by global leading organizations